Air ducts

Air conditioning solutions are individual solutions. That is why we offer you our innovative air ducts, which we manufacture according to your project.

All air ducts from a single source

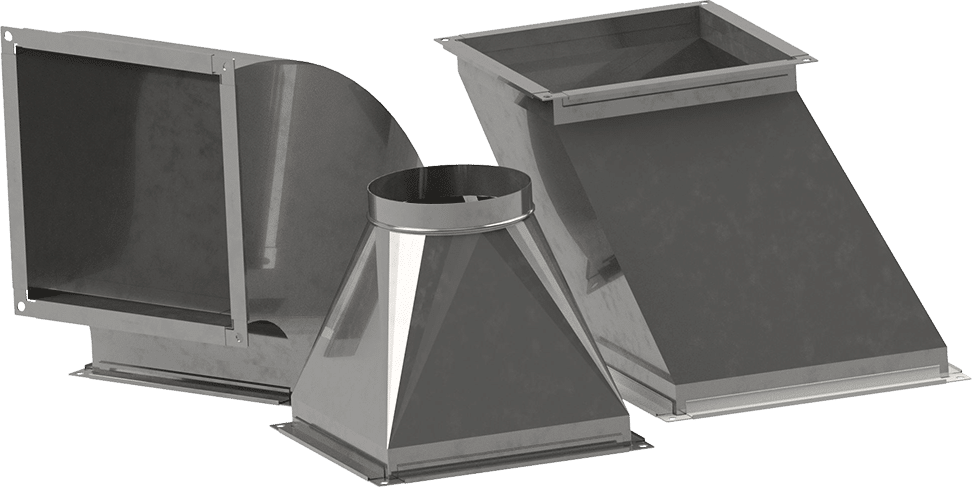

We manufacture folded ventilation ducts in all variants, as well as welded ducts and pipelines. Our product range also includes spiral ducts and fittings.

Energy saving and hygiene made easy

Our products comply with the current standards for air tightness and hygiene. We are also guided by the latest research findings.

Quality from Trier

All products are manufactured exclusively at our high-tech site in Trier. From there, delivery is made directly to the construction site.

Gradation flange profiles

20 mm up to and including 1000 mm edge length

30 mm up to and including 2000 mm edge length

40 mm from 2001 mm edge length

Materials / Materials

Sheet steel

Stainless steel (1.4301+1.4571)

Aluminium

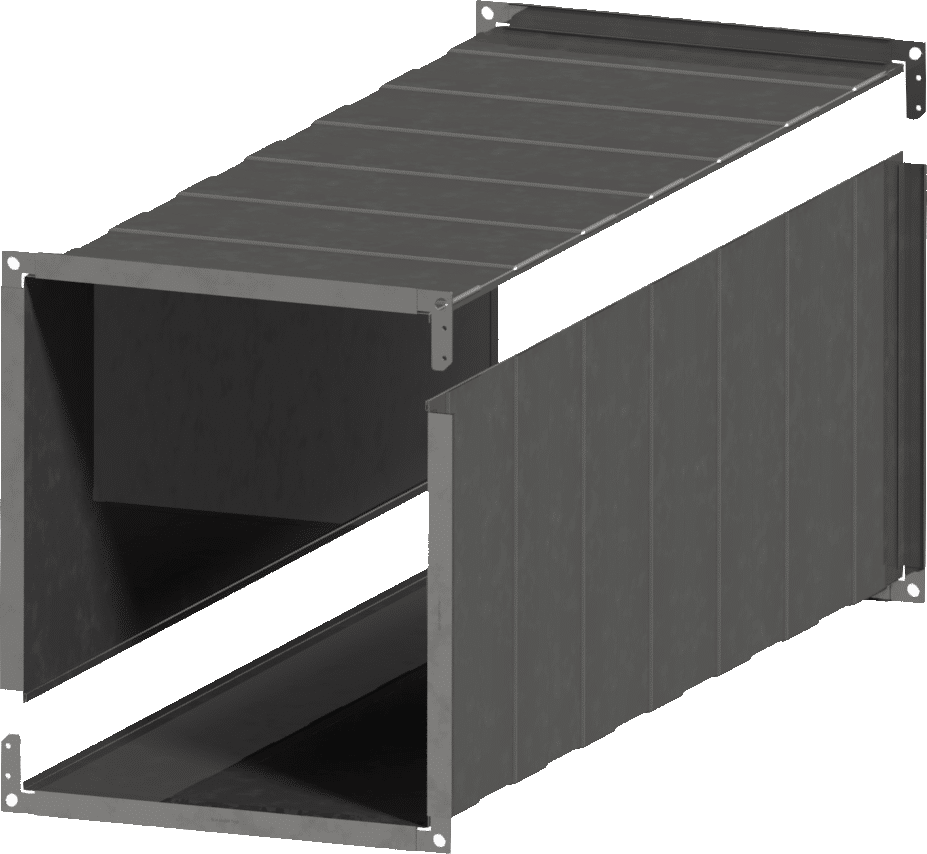

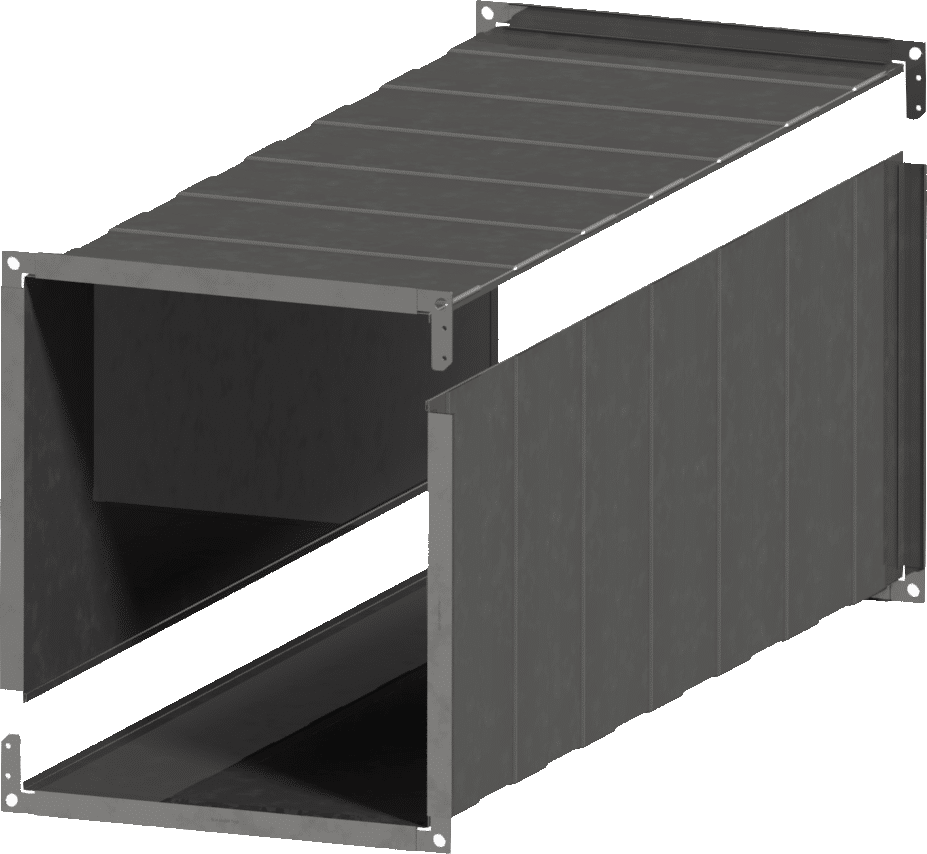

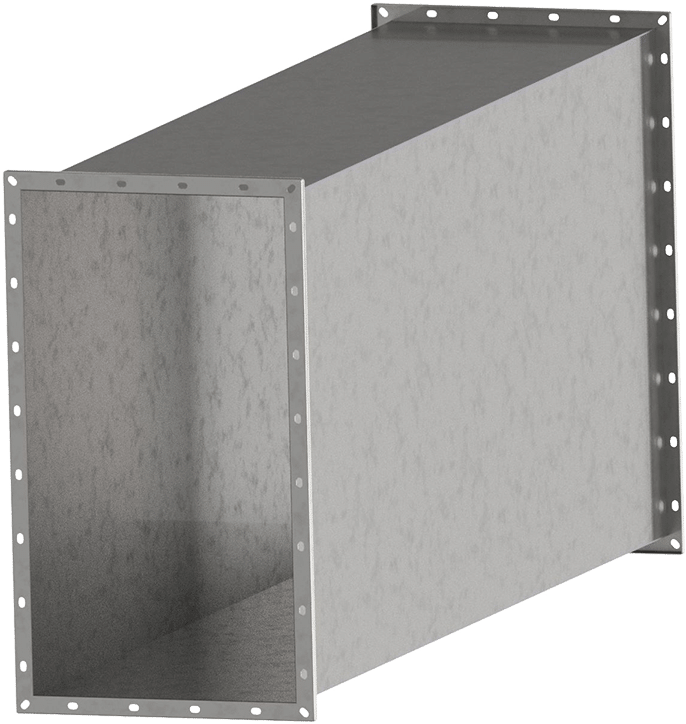

folded ventilation ducts

Standard version

- Design according to DIN EN 1505, 1507 and DIN 18379

- Pressure stages: Low pressure, medium pressure and high pressure according to VDI 3803

- Tightness classes: A, B and C according to DIN EN 1507

- Sheet quality: Cold-rolled sheet, grade D x 51D + Z275 MA, surface treatment C, zinc coating of at least 275 g/sqm on both sides.

- Connection with light profile frame DIN 24192, with 4-bolt corner connection, spot-welded, corners sealed

- Standard shot length: 1500 and 1000 mm

- Shot length: 3000 mm max.

- Stiffening according to BLH standard

- Light sheet metal arrangement according to DIN 1505

- Wall anti-drumming by means of beads

folded ventilation ducts

Special versions

Ventilation ducts for export

- Straight L-shaped ducts

- Moulded parts with snap fold

- Space-saving transport in wooden boxes, assembly on site

Ventilation ducts for industry

- For special requirements with regard to rigidity, inherent stability and oversizes. Design: 40 mm module edging and attached batten | Variable sheet thickness

- Flange connection selectable: 40 mm light profile | angle iron | flat frame

- Additional stiffening inside and/or outside with Z-profile/hat profile

Coated

Channels

- Channels with powder coating or wet painting

- Special coatings for chlorinated exhaust air possible

Insulated, double-walled vent ducts

- Insulation with non-combustible mineral wool, e.g. 20-50 mm thick.

- Alternatively single-walled with Armaflex inner insulation

- Stiffening according to BLH standard

- Wall anti-drumming by means of beads

Ventilation ducts for export

- Straight L-shaped ducts

- Moulded parts with snap fold

- Space-saving transport in wooden boxes, assembly on site

Ventilation ducts for industry

- For special requirements with regard to rigidity, inherent stability and oversizes. Design: 40 mm module edging and attached batten | Variable sheet thickness

- Flange connection selectable: 40 mm light profile | angle iron | flat frame

- Additional stiffening inside and/or outside with Z-profile/hat profile

Coated channels

- Channels with powder coating or wet painting

- Special coatings for chlorinated exhaust air possible

Insulated, double-walled vent ducts

- Insulation with non-combustible mineral wool, e.g. 20-50 mm thick.

- Alternatively single-walled with Armaflex inner insulation

- Stiffening according to BLH standard

- Wall anti-drumming by means of beads

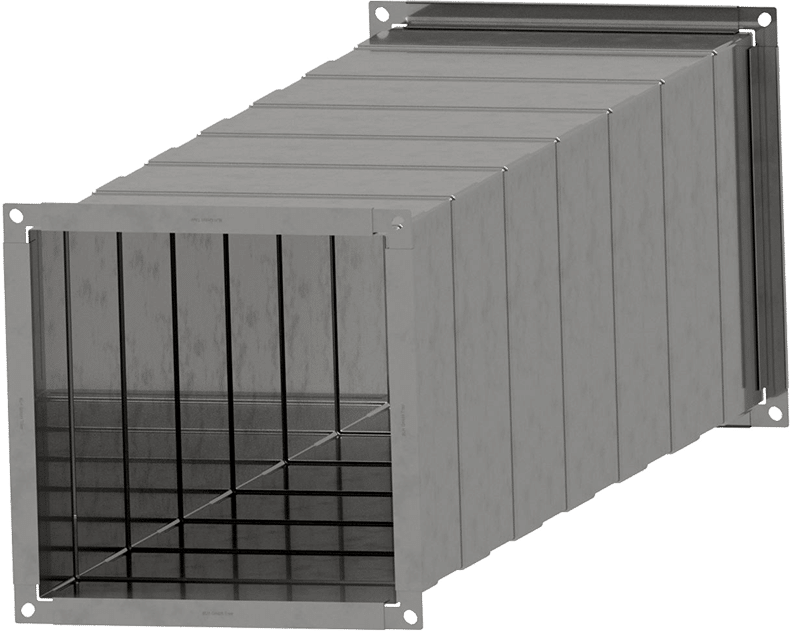

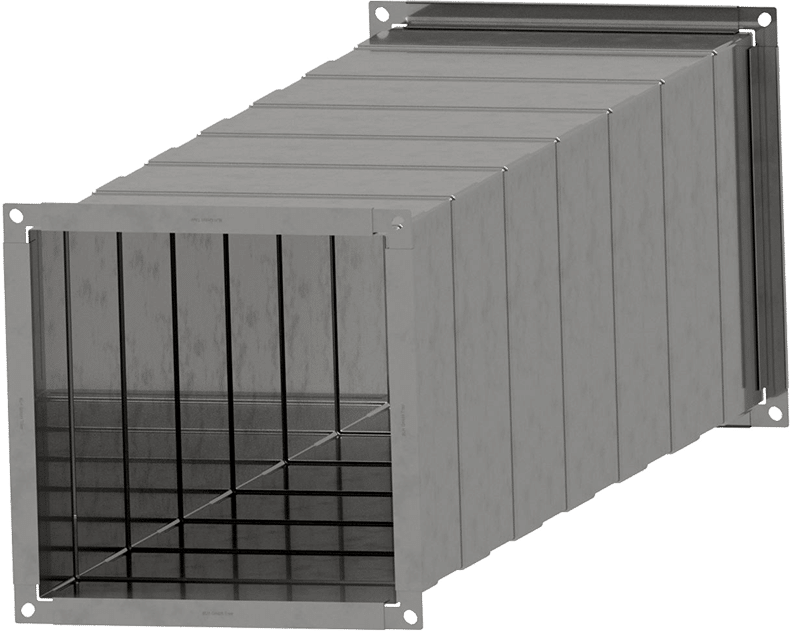

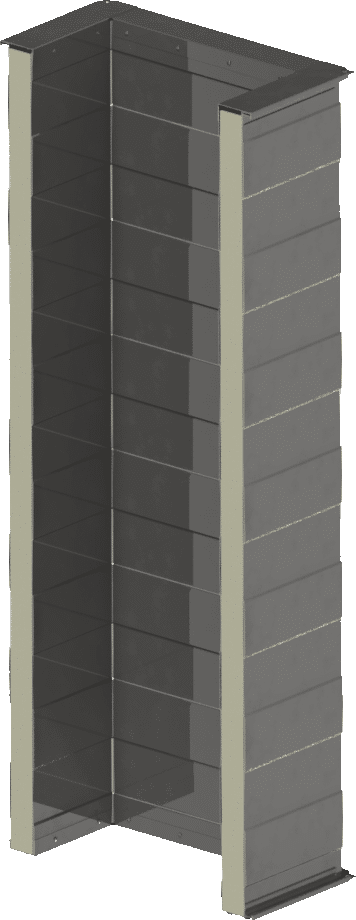

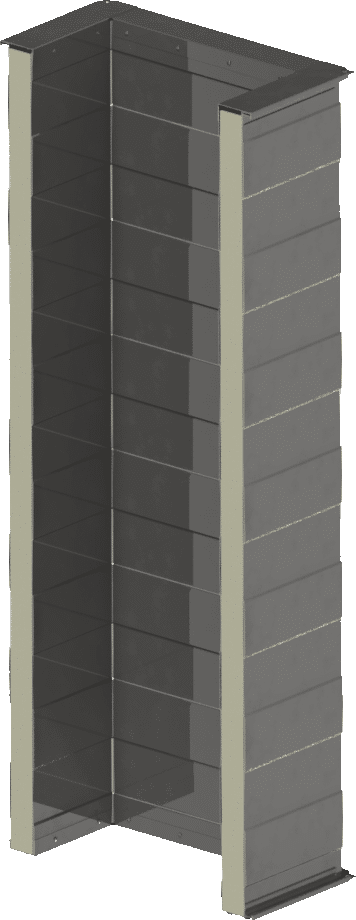

MX smoke extraction ducts

Effective smoke extraction with smoke extractor MX

In a fire, there is not only an enormous potential danger in the fire, but also in the smoke. Many deaths occur as a result of heavy smoke development. In contrast to sprinkler systems, smoke extraction systems react directly to the smoke and thus considerably reduce the danger. In order to be able to offer you optimum quality in this area as well, we have expanded our product range with the MX smoke extraction system.

The smoke vent MX is a smoke extraction duct with CE certificate 0761-CPR-0513 according to EN 12101-7:2011. Product according to Building Rules List B Part 1 under Lfd. No. 1.17.6 of the German Institute for Building Technology (DIBt), edition 2015/1.

The test was carried out at room temperature with 1500 Pa negative pressure and at 600°C with 500 Pa negative pressure over a service life of 120 min. in accordance with DIN 18232-6 and prEN 1366-9. We also supply the corresponding fire gas expansion joints. The ducts are connected to the expansion joints using an SBM 30 frame profile.

applications

Industry

Power stations

Process air

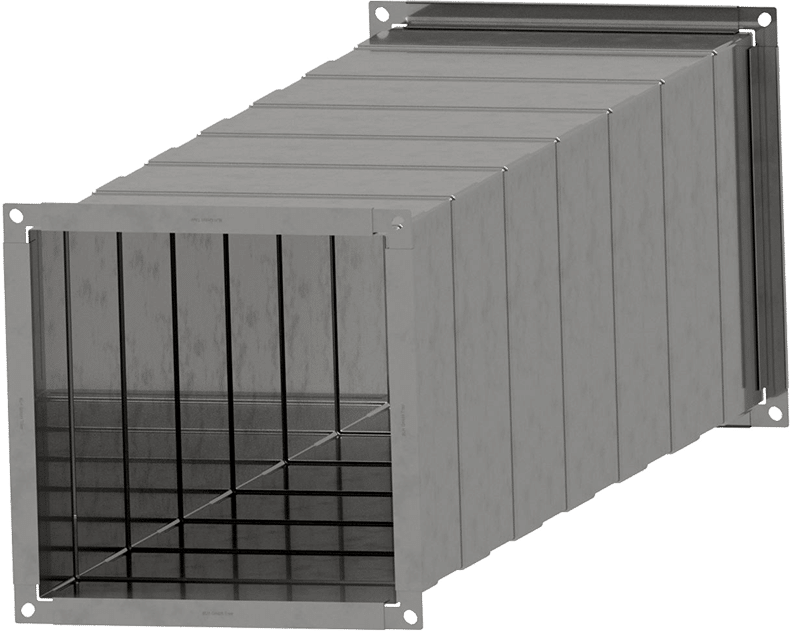

Welded ducts & fittings

Standard version

- Tightness class C and D according to DIN EN 1507

- Oil- and grease-tight design possible

- Connection via moulded-on flanges or attached angle iron frames

- Standard duct length 1380 mm with moulded frame 40/20

- Frame perforation according to BLH standard, hole spacing 100 mm, adaptation to other hole spacings possible

- Black plate also with corrosion protection through surface treatment

- Design & sheet thickness according to DIN EN 1505 or DIN 24190 / 24191

- Low pressure, pressure stage 1/4 as well as medium pressure, pressure stage 2/5

- Tightness classes according to EN 1507 and DIN 24194

- Sheet quality: Cold-rolled sheet, grade D x 51D + Z275 MA, surface treatment C, zinc coating of at least 275 g/sqm on both sides.

- Connection with light profile frame DIN 24192, with 4-bolt corner connection, spot-welded, corners sealed

- Connection options: Variant 1, Variant 2, Variant 3

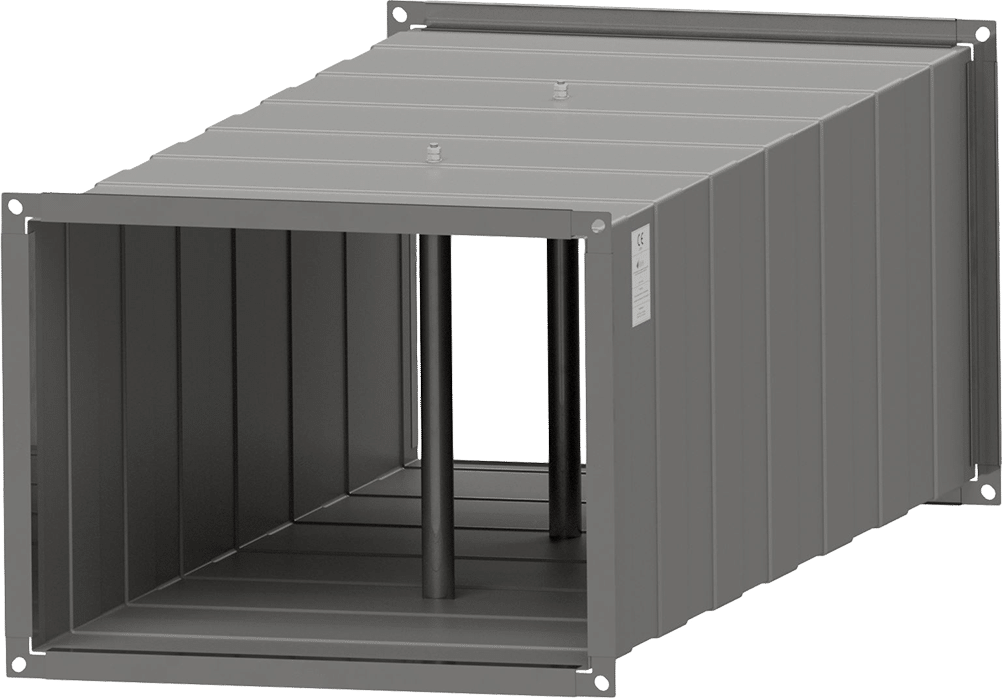

welded ventilation ducts

High quality welded ventilation ducts

Variant 1

Flange made of hot-rolled angle section according to DIN 1028 welded tightly on the inside or outside all around according to DIN 24 192-W1.

Types of construction

- Sheet steel black, connection W2 according to DIN 24192 single welded or stapled

- Black sheet steel, connection W1 to DIN 24192 double-welded or nekal-tight

Variant 2

Flange made of hot rolled angle section according to DIN 1028 spot welded (resistance spot welding) and duct ends flanged 10 mm according to DIN 24 192-W2, corners welded.

Types of construction

- Sheet steel black, connection W2 to DIN 24192 behind board

Variant 3

Depending on the expected differential pressures and air velocities, the ducts are stiffened as required by means of welded-in pipe supports or additional profiles welded on the inside or outside.

Types of construction

- Black sheet steel, moulded connection with rear edge

- Galvanised sheet steel, moulded connection with rear edge

We also manufacture welded ducts in the materials:

Stainless steel

(1.431, 14571 or other stainless steels according to DIN 17440)

- After processing, pickled and neutralised again (IIa or IIc according to DIN 17440), additionally passivated on request.

- Brushed surface (q according to DIN 17440)

- Weld seams locally pickled and neutralised or brushed

Sheet steel

(St12, StW22, St37)

- Without surface coating

- Inside and/or outside additionally primed

- Inside and/or outside additionally top-coated

- Powder-coated inside and/or outside

- Hot-dip galvanised in full bath according to DIN 50976

- Strip galvanised (sendzimir galvanised)

Aluminium

(1.431, 14571 or other stainless steels according to DIN 17440)

- Pure aluminium AL 99.5

- ALMg3 (seawater resistant)

- Inside and/or outside additionally top-coated

Copper

(1.431, 14571 or other stainless steels according to DIN 17440)

- Ideal for antibacterial applications

- Hospitals and office buildings

Material

Steel

Stainless steel

Aluminium

Welded piping & fittings

Standard version

- Firmly welded strands up to 14m length

- Individual pipe sizes and degrees of segment bends

- Standard flanges according to DIN 24154 series 1 or series 2

- Flanges loosely behind board or firmly welded

- Applications and pressure ratios according to DIN 24151

- Corrosion protection possible through surface coating

- Design & sheet thickness according to DIN EN 1505 or DIN 24190 / 24191

- Low pressure, pressure stage 1/4 as well as medium pressure, pressure stage 2/5

- Tightness classes according to EN 1507 and DIN 24194

- Sheet quality: Cold-rolled sheet, grade D x 51D + Z275 MA, surface treatment C, zinc coating of at least 275 g/sqm on both sides.

- Connection with light profile frame DIN 24192, with 4-bolt corner connection, spot-welded, corners sealed

- Connection options: Variant 1, Variant 2, Variant 3

Variant 1

Flange made of hot-rolled angle section according to DIN 1028 welded tightly on the inside or outside all around according to DIN 24 192-W1.

Variant 2

Flange made of hot rolled angle section according to DIN 1028 spot welded (resistance spot welding) and duct ends flanged 10 mm according to DIN 24 192-W2, corners welded.

Variant 3

Depending on the expected differential pressures and air velocities, the ducts are stiffened as required by means of welded-in pipe supports or additional profiles welded on the inside or outside.

welded piping

Special version

The following special designs or agreements are possible on request:

- Leak test (nekal test, dye penetrant test, radiographic test, etc.)

- Material allocation according to DIN 50049

- Individual packaging depending on requirements

- Higher tolerances and welding seam grades

- Weld quality: according to EN 25817/ D

- Welding method: Manual welding seams MAG or optionally TIG

- Longitudinal welds fully mechanised welded (plasma or TIG)

- Manufacturing tolerances: DIN 24151 or DIN 8570 C/G

Dimensions (as an example)

20 mm up to and including 1000 mm edge length

30 mm up to and including 2000 mm edge length

40 mm from 2001 mm edge length

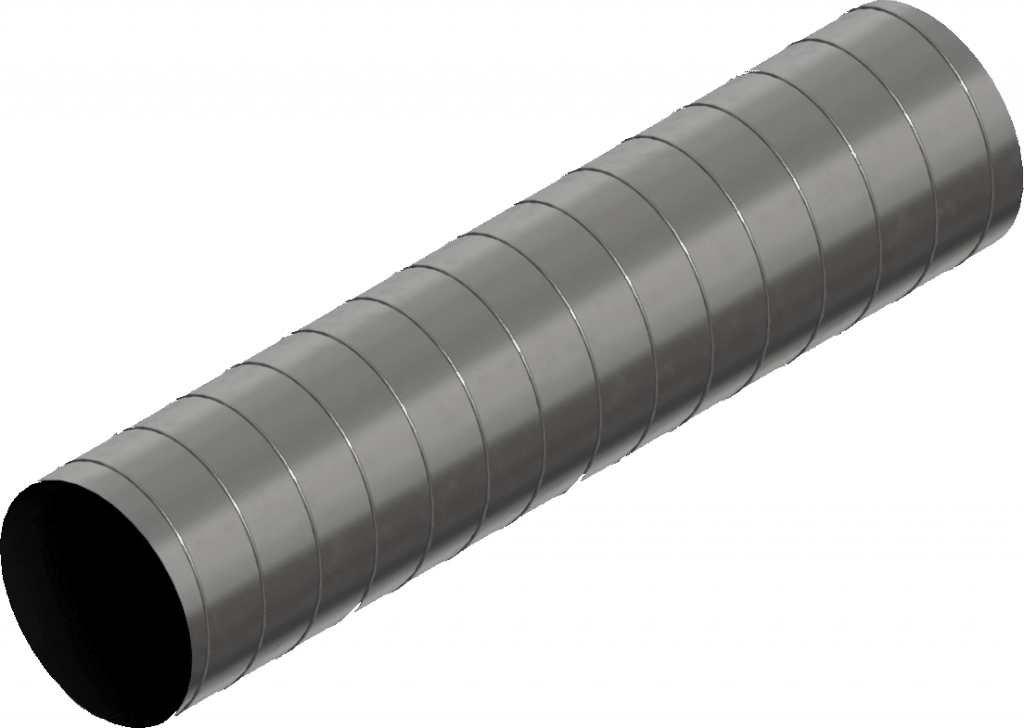

Dimensions

Ø 80 to 1250 mm

Standard length 3000 mm

Tightness class D

Spiral ducts

Standard version

- Spiral duct, perforated, insulated, plain duct

- Moulded parts, silencers, flexible pipe and outlets

- Pipe system according to DIN EN 12237 and DIN EN 150

- Hygienic version with end caps possible

- Galvanised steel and stainless steel

gallery

Impressions of our ventilation ducts